#HDPE Prices

Explore tagged Tumblr posts

Text

HDPE Prices: Market Analysis, Trend, News, Graph and Demand

High Density Polyethylene (HDPE) is one of the most widely used thermoplastics in the global polymer industry, valued for its strength, versatility, and chemical resistance. As demand for plastic materials continues to rise across sectors such as packaging, construction, automotive, and agriculture, the HDPE market has become a focal point for manufacturers, suppliers, and investors alike. Over the past few years, HDPE prices have demonstrated significant fluctuations, driven by a complex interplay of raw material availability, energy costs, geopolitical dynamics, and regional demand-supply imbalances. Understanding the price movements of HDPE is crucial for stakeholders across the supply chain, as it directly impacts production costs, profit margins, and procurement strategies.

One of the primary factors influencing HDPE prices is the cost of its main feedstock—ethylene. Ethylene is derived from crude oil and natural gas, making HDPE prices sensitive to fluctuations in global energy markets. When oil and gas prices surge due to geopolitical tensions, supply disruptions, or changes in OPEC production quotas, the cost of ethylene increases, thereby pushing up HDPE production costs. Conversely, a drop in crude oil prices tends to ease the price pressure on HDPE, although the response can vary depending on downstream market demand. Another critical factor is the production capacity and operational efficiency of petrochemical plants. Any unplanned shutdowns, maintenance schedules, or delays in capacity expansion can result in temporary shortages, leading to price spikes. In contrast, oversupply due to new capacity additions, especially in Asia and the Middle East, can exert downward pressure on prices.

Get Real time Prices for Linear High Density Polyethylene (HDPE): https://www.chemanalyst.com/Pricing-data/hdpe-7

Regional dynamics also play a pivotal role in shaping HDPE market prices. In North America, HDPE prices are often influenced by shale gas-based ethylene production, which offers cost advantages compared to naphtha-based production in Europe and parts of Asia. This cost efficiency gives North American producers a competitive edge in the export market, particularly when global demand is strong. In Asia, the HDPE market is heavily impacted by China, which is not only a major producer but also the largest consumer of HDPE. Any shifts in China’s economic activity, import policies, or environmental regulations can have a ripple effect on global HDPE prices. For instance, a slowdown in Chinese manufacturing or construction activities can reduce HDPE consumption, leading to an oversupplied market and falling prices. On the other hand, stimulus measures or infrastructure investments can boost demand and support higher price levels.

Seasonal trends also contribute to HDPE price variability. Demand typically rises in the first half of the year, driven by the agricultural season in countries like India and the construction season in temperate regions. This increase in demand can lead to firmer prices, especially if it coincides with supply constraints. During the second half of the year, demand may soften due to inventory adjustments and reduced consumption, resulting in a more bearish price outlook. Moreover, shipping and logistical challenges can further complicate price movements. Congestion at major ports, container shortages, and high freight rates can limit the availability of HDPE in certain regions, contributing to localized price surges.

Environmental regulations and the global push for sustainability are increasingly affecting the HDPE market. As more governments introduce policies aimed at reducing plastic waste and promoting recycling, the demand for virgin HDPE could be affected. However, despite the growing interest in recycled HDPE (rHDPE), the supply of high-quality recycled material is still limited, and it cannot fully replace virgin HDPE in applications requiring stringent quality standards. As a result, the overall impact of recycling on HDPE prices remains moderate but is expected to grow over time as technology improves and regulations tighten. Market sentiment and speculative activity can also sway HDPE prices in the short term. Traders often respond to news related to feedstock trends, weather disruptions, or trade policies, creating volatility even in the absence of fundamental supply-demand changes.

Looking ahead, HDPE prices are likely to remain subject to global macroeconomic conditions, particularly as inflation, interest rates, and consumer spending influence industrial output and packaging needs. Emerging economies are expected to drive HDPE demand growth, especially in the packaging and infrastructure sectors. Investments in circular economy initiatives and innovations in polymer processing will continue to shape the market landscape. Additionally, the adoption of digital technologies in supply chain management and pricing analytics is improving market transparency and enabling more strategic decision-making by buyers and sellers.

In conclusion, the HDPE market is characterized by a multitude of interrelated factors that collectively influence its pricing trends. From raw material costs and production capacity to regional dynamics and environmental considerations, each element plays a role in determining the market’s direction. Stakeholders in the HDPE industry must stay informed of these variables and adapt quickly to market signals to remain competitive. With global demand projected to rise and supply chains becoming increasingly complex, understanding HDPE price movements is more critical than ever for making informed business decisions.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#HDPE Price#HDPE Prices#HDPE Pricing#High Density Polyethylene Price Monitor#India#united kingdom#united states#Germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

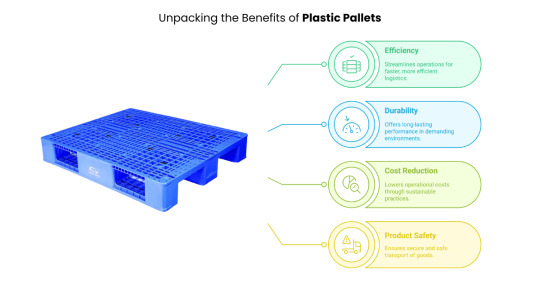

Plastic Pallets: The Smart Choice for Modern Material Handling

In today’s fast-paced industrial world, efficiency and durability are key factors in material handling. Businesses are constantly looking for solutions that optimize logistics, reduce costs, and ensure product safety.

Thus, following are the advantages which have made plastic pallets the best fit for every industry.

Why Choose Plastic Pallets?

Durability & Strength Plastic Pallets are made with superior materials that can bear load and accordingly the conditions, extreme. These are sturdy and built to last, saving you money in the long run as you don't have to keep replacing them.

Hygienic & Easy to Clean Hygiene becomes the most important factor in the industry like food processing, pharmaceuticals, etc. Plastic Plastic pallets are great because they don’t soak up moisture, which helps keep germs and bacteria at bay. This feature makes them super easy to clean and sanitize!

Lightweight & Easy to Handle Logistics aspect with huge importance on handling efficiency. Because they are lightweight and incredibly durable, they reduce physical labour, save money on shipping, and improve workplace safety.

Consistent Design & Standardization Unlike traditional options, Plastic Pallets maintain a uniform size and shape, ensuring smooth automation and stacking. They are precision-made, removing inconsistencies, and improving operational efficiency.

Eco-Friendly & Recyclable Plastic pallets contribute to the green supply chains in businesses worldwide by being made from recyclable materials and being reusable multiple times. In this case, sustainability becomes a core priority as a businesses.

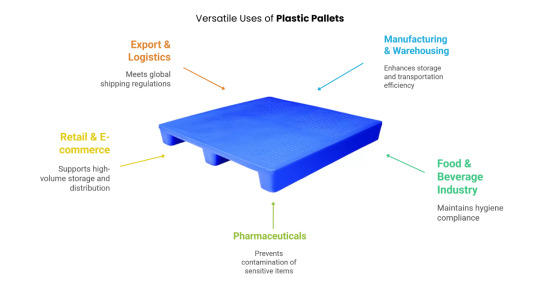

Applications of Plastic Pallets

Manufacturing & Warehousing : These storage systems are great for efficiently storing and transporting goods.

Food & Beverage Industry: Ensures compliance with hygiene standards.

Pharmaceuticals: prevents contamination of delicate items.

Retail & E-commerce: Supports high-volume storage and distribution.

Export & Logistics: Offers compliance with global shipping regulations.

The Future of Material Handling

Designating Emerging Industry Standards for Plastic Pallets While their longevity, efficacy, and environmentally friendly features make them the go-to choice for companies looking for long-term solutions.

Upgrade to plastic pallets today and experience seamless, cost-effective, and sustainable material handling for your operations with Swift Technoplast.

#pallet plastic#plastic pallets manufacturer#plastic pallets supplier#hdpe pallet#plastic pallets for sale near me#plastic pallets manufacturers in india#Plastic pallet price#plastic pallet near me#pvc pallets#plastic pallets

0 notes

Text

How Chemical Plastic Bottle Blow Molding Machines Work: A Complete Guide

Introduction The manufacturing industry has witnessed a significant rise in the use of chemical plastic bottle blow molding machines due to the increasing demand for durable plastic containers. These machines are essential for producing high-quality plastic bottles used in the chemical, pharmaceutical, food, and cosmetic industries. This guide will walk you through the working process, types,…

#Automatic Blow Molding Machine Price#Best Blow Molding Machine for Chemicals#Blow Molding Machine for Chemical Bottles#chemical plastic bottle blow molding machine#HDPE Chemical Bottle Making Machine#Molding Machines#Plastic Bottle Manufacturing Process

0 notes

Text

HDPE Pipe - The Future of Strong and Reliable Piping - Sudhakar Group

HDPE Pipe: A Revolutionary Solution for Durable and Sustainable Piping

In the world of piping systems, the demand for strong, reliable, and cost-effective materials is ever-increasing. One such material that has been gaining immense popularity is HDPE (High-Density Polyethylene). Known for its excellent strength-to-density ratio, HDPE pipe is widely used in a variety of industries, from water distribution systems to sewage lines, and even in gas pipelines. As a result, HDPE pipe has become a go-to choice for both residential and commercial projects.

The popularity of HDPE pipe is driven by its ability to withstand high pressures, resist corrosion, and provide a long service life with minimal maintenance. Sudhakar Group, one of the leading hdpe pipe manufacturers, has contributed to the growth and development of HDPE pipe systems by offering high-quality products that meet industry standards. Their commitment to innovation and product excellence makes them a trusted name in the piping industry.

CPVC Pipe: A Complementary Solution for Safe Water Distribution

While HDPE pipe is widely used for many applications, another popular option in the piping industry is CPVC (Chlorinated Polyvinyl Chloride) pipe. CPVC pipes are known for their excellent resistance to chemicals and high temperatures, making them ideal for water distribution systems, particularly in areas that require hot water supply or where chemical exposure is a concern.

Sudhakar Group manufactures both HDPE and CPVC pipes, providing customers with a comprehensive range of piping solutions. Whether you are designing a plumbing system for a new building or upgrading an existing one, CPVC pipes offer a safe, reliable, and long-lasting option for water distribution. By offering both HDPE and CPVC pipes, Sudhakar Group caters to a wide variety of customer needs, ensuring that their piping systems are built to last.

Why Choose Sudhakar Group Among Leading HDPE Pipe Manufacturers?

As one of the top hdpe pipe manufacturers, Sudhakar Group has built a reputation for providing high-quality products that are both durable and cost-effective. Here are some reasons why Sudhakar Group stands out in the industry:

Superior Durability: HDPE pipes are resistant to a variety of environmental factors, including chemicals, UV rays, and abrasion. Sudhakar Group’s HDPE pipes are designed to withstand these harsh conditions, providing a long-lasting solution for a wide range of applications.

Custom Solutions: Sudhakar Group offers tailored piping solutions based on the unique requirements of each project. Whether it’s a residential, commercial, or industrial application, Sudhakar Group works with clients to deliver the perfect piping system.

Cutting-Edge Technology: Sudhakar Group utilizes the latest technology in manufacturing HDPE pipes, ensuring that they meet the highest standards of quality and performance. This technological edge allows them to produce pipes that offer superior strength, flexibility, and resistance to damage.

Wide Product Range: In addition to HDPE pipes, Sudhakar Group also offers a variety of other piping products, including CPVC pipes and plastic pipe systems for different applications. Whether you are in need of pipes for water supply, drainage, or chemical transport, Sudhakar Group has a product for every need.

Eco-Friendly Solutions: HDPE pipes are known for their environmentally friendly properties. They are non-toxic, reusable, and recyclable, which makes them a sustainable choice for modern piping systems. Sudhakar Group prioritizes sustainability, ensuring that their products meet environmental regulations and contribute to greener solutions.

The Advantages of Using HDPE Pipe in Various Industries

The use of HDPE pipes is growing across industries, thanks to their remarkable properties. Some of the key advantages of HDPE pipes include:

High Strength and Durability: HDPE pipes can withstand high pressure, making them ideal for applications where durability is critical. They are also resistant to impact, ensuring long-term reliability even in challenging conditions.

Corrosion Resistance: Unlike traditional metal pipes, HDPE pipes do not corrode, which significantly reduces the need for maintenance and repairs over time. This makes them an excellent choice for water and gas distribution systems.

Flexibility: HDPE pipes are flexible and can be easily bent and shaped to fit specific installation requirements. This flexibility reduces the need for fittings, which makes the installation process more efficient and cost-effective.

Cost-Effective: HDPE pipes are generally more affordable than other types of pipes due to their durability and ease of installation. The long lifespan of HDPE pipes means fewer replacements and repairs, making them a cost-effective choice for both residential and commercial projects.

Plastic Pipe Manufacturers and the Growing Demand for HDPE Solutions

The demand for plastic piping solutions is on the rise, driven by the growing need for reliable, low-maintenance, and eco-friendly alternatives to traditional metal pipes. As one of the leading plastic pipe manufacturers, Sudhakar Group has been at the forefront of this change, offering high-quality HDPE pipes that meet the evolving needs of the market.

With the growing trend towards sustainable construction and infrastructure development, the demand for HDPE pipes is expected to continue increasing. Their versatility, durability, and eco-friendly nature make them an ideal choice for modern piping systems in industries such as agriculture, construction, water treatment, and even mining. Sudhakar Group continues to innovate and expand its product offerings, ensuring that customers have access to the best piping solutions available.

Conclusion: Choose Sudhakar Group for Reliable HDPE Pipes

When it comes to selecting the best HDPE pipes for your project, Sudhakar Group is the ideal partner. As one of the leading hdpe pipe manufacturers, Sudhakar Group provides high-quality, durable, and cost-effective piping solutions that meet the demands of modern infrastructure. Their commitment to quality and innovation ensures that their products deliver optimal performance for both residential and commercial applications.

Sudhakar Group’s range of products, including HDPE pipes, CPVC pipes, and other plastic pipes, provide customers with the flexibility to choose the right solution for any project. Their eco-friendly approach, coupled with cutting-edge manufacturing technology, ensures that their pipes are not only durable but also environmentally responsible.

For businesses seeking plastic pipe manufacturers or exploring more sustainable piping options, Sudhakar Group remains the trusted name in the industry. In addition to their comprehensive piping solutions, they also offer other products, including wire and cable manufacturers and upvc window manufacturers, to support various construction and industrial needs.

#HDPE PIPE#HDPE PIPE MANUFACTURERS#CPVC PIPE#plastic pipe manufacturers`#wire and cable manufacturers#electrical wire#wire manufacturers#upvc window manufacturers#upvc windows and doors#upvc windows price

0 notes

Text

Sudhakar Group is a leading HDPE pipe manufacturer offering high-quality HDPE pipes, CPVC pipes, and other plastic piping solutions. As trusted plastic pipe manufacturers, we provide durable, cost-effective products for diverse industries. Our HDPE pipes are known for their strength, longevity, and resistance to corrosion. We specialize in delivering reliable solutions for water, gas, and sewage systems. Sudhakar Group’s CPVC pipes offer excellent heat resistance and are ideal for plumbing applications. Explore our extensive range of HDPE pipes and CPVC pipes for all your construction needs. Trust Sudhakar Group for top-notch quality and performance."

This meta description efficiently incorporates all the target keywords while describing the products and brand strengths.

#upvc window manufacturers#upvc windows and doors#upvc windows price#wire manufacturers#electrical wire#wire and cable manufacturers#plastic pipe manufacturers`#cpvc pipe#hdpe pipe#hdpe pipe manufacturers

0 notes

Text

Pallet Wrapper Machine Manufacture - Innovative WrapTech Pvt. Ltd.

Leading Pallet Wrapper Machine Manufacturer providing safe, effective, and long-lasting pallet packaging solutions. Increase your output right now.

#Wrapping Machine#Stretch Wrapping Machine Manufacturer#Stretch Wrapping Machine Price#Innovative Wraptech Company#Coil Stretch Manufacturer and Supplier#Vertical Coil Wrapping Machine Manufacturer#Coil Stretch Wrapper Manufacturer#Industrial Pallet Wrapping Machine Supplier#Shrink Wrapping Machines Manufacturers#Coil Stretch Wrapping Machine#Coil Wrapping Machine#Coil Wrapping Machine Manufacturer#Vertical Coil Stretch Wrapping Machine#Vertical Coil Wrapping Machine#Horizontal Coil Stretch#Coil Stretch Wrapping Machine price#Horizontal Coil Wrapping Machine#Coil Master Wrapper Machine#SS Wire Coil Packing Machine#SS Wire Coil Packing Machine Manufacturer#G.I Wire Coil Wrapping Machine#G.I Wire Film Wrapping Machine#Semi Automatic Vertical Coil Wrapping Machine#Vertical Coil Packing Machine#Rope Wire Coil Wrapping Machine#Drip Irrigation Pipe Wrapping Machine#Drip Pipe Wrapping Machine#Galvanized Wire Packing Machine#Big HDPE Pipe Stretch Wrapping Machine#Lateral Pipe packaging machines

0 notes

Text

HDPE Pipe Manufacturer & Suppliers In Hyderabad

Leading HDPE Pipe Manufacturers in Hyderabad

When it comes to reliable and durable piping solutions, HDPE pipe manufacturers in Hyderabad like Sudhakar Group are trusted by businesses, industries, and homeowners alike. HDPE (High-Density Polyethylene) pipes are known for their strength, corrosion resistance, and long service life. These pipes are ideal for a wide range of applications, from water supply systems to sewage systems, and are commonly used in construction and industrial sectors. As one of the top HDPE pipe manufacturers, Sudhakar Group is committed to providing high-quality pipes that meet global standards for safety and performance.

HDPE pipes offer a number of advantages over traditional pipes, such as PVC and metal pipes. They are flexible, lightweight, and easy to install, which makes them a preferred choice for many types of pipelines. Sudhakar Group, based in Hyderabad, ensures that all their HDPE pipes are made from the best raw materials, ensuring longevity and excellent performance for all types of projects.

Wire and Cable Manufacturers – Ensuring Quality and Safety

In addition to being a leading name in the HDPE pipe manufacturers sector, Sudhakar Group is also recognized as one of the most trusted wire and cable manufacturers in the region. Whether it's for residential, industrial, or commercial purposes, electrical wiring plays a crucial role in the safety and efficiency of any electrical system. Sudhakar Group’s extensive experience in manufacturing high-quality electrical wires ensures that you get the best possible solutions for your wiring needs.

Sudhakar Group's commitment to quality and safety extends to their range of cables and wires. Each product undergoes rigorous testing and quality checks to ensure compliance with international safety standards. With the rise in demand for reliable electrical systems in homes and industries, it is essential to work with reputable manufacturers. Sudhakar Group, as trusted wire and cable manufacturers, provides products that ensure both performance and safety, making them a preferred choice for electrical wiring solutions.

Why Choose Sudhakar Group for HDPE Pipes?

There are several reasons why Sudhakar Group stands out among HDPE pipe manufacturers in Hyderabad. The company has built a reputation for delivering durable and cost-effective piping solutions that meet the needs of a wide range of industries. Some of the reasons why Sudhakar Group is trusted by so many customers include:

High-Quality Raw Materials: Sudhakar Group uses only the finest quality raw materials in the manufacturing of HDPE pipes, ensuring that every pipe is resistant to corrosion, wear, and tear.

Variety of Sizes and Specifications: Whether you need HDPE pipes for water supply, drainage, or industrial applications, Sudhakar Group offers a wide range of sizes and specifications to suit different project requirements.

Long Lifespan: HDPE pipes manufactured by Sudhakar Group are designed for durability and can withstand harsh environmental conditions, making them a long-term investment.

Cost-Effective Solutions: By providing high-quality products at competitive prices, Sudhakar Group ensures that customers get the best value for their money.

Compliance with Industry Standards: Sudhakar Group’s HDPE pipes are manufactured in accordance with international standards, ensuring safety and reliability.

Sudhakar Group's expertise as HDPE pipe manufacturers guarantees that all products are built to last and offer superior performance for various applications.

HDPE Pipe Applications

HDPE pipes are versatile and can be used in a variety of applications. Here are some common uses of HDPE pipes in different industries:

Water Supply Systems: HDPE pipes are widely used in water distribution systems, offering a reliable and cost-effective solution for transporting drinking water.

Sewage and Drainage Systems: Due to their resistance to corrosion and ability to handle high-pressure liquids, HDPE pipes are ideal for sewage and drainage applications.

Agriculture: HDPE pipes are used in irrigation systems for efficient water management in agricultural fields.

Oil and Gas: In the oil and gas industry, HDPE pipes are used for transporting oil and gas products because of their durability and resistance to chemicals.

Telecommunication: HDPE pipes are used for protecting cables in telecommunication systems, ensuring they remain safe from environmental damage.

With Sudhakar Group’s high-quality HDPE pipes, you can ensure that your projects are completed with the best materials that will last for decades.

The Benefits of HDPE Pipes Over Other Materials

There are several reasons why HDPE pipes are preferred over traditional piping materials like PVC and metal pipes. As one of the top HDPE pipe manufacturers in Hyderabad, Sudhakar Group highlights the following benefits:

Durability: HDPE pipes are highly durable and can withstand harsh weather conditions, chemicals, and physical stress, making them ideal for long-term use in a wide range of environments.

Flexibility: Unlike rigid pipes, HDPE pipes are flexible and can be installed easily even in tight or irregular spaces.

Corrosion Resistance: HDPE pipes do not corrode like metal pipes, ensuring that the water and other fluids transported through them remain clean and safe.

Cost-Effectiveness: HDPE pipes are relatively inexpensive compared to other materials, offering an affordable solution without compromising on quality.

Environmentally Friendly: HDPE pipes are made from recyclable materials, making them a more eco-friendly option compared to plastic and metal pipes.

As HDPE pipe manufacturers, Sudhakar Group continues to innovate and provide solutions that meet the growing demand for high-quality, reliable, and environmentally friendly piping options.

Sudhakar Group’s Other Offerings

In addition to being recognized as one of the best HDPE pipe manufacturers, Sudhakar Group offers a variety of other products to cater to the diverse needs of their clients:

CPVC Pipes: Sudhakar Group also manufactures high-quality CPVC pipes that are perfect for hot and cold water applications in residential and industrial settings.

Plastic Pipes: As leading plastic pipe manufacturers, Sudhakar Group provides a wide range of plastic pipes for different construction and industrial applications.

UPVC Windows and Doors: Sudhakar Group manufactures durable and energy-efficient UPVC windows and doors designed to provide superior insulation and reduce energy consumption. They offer UPVC windows price at competitive rates, ensuring that you get the best value for your money.

Conclusion

Sudhakar Group, a top name among HDPE pipe manufacturers in Hyderabad, offers a broad range of high-quality piping solutions for various applications. From water supply and sewage systems to agriculture and telecommunication, HDPE pipes are ideal for industries requiring long-lasting, reliable, and cost-effective materials. As one of the leading plastic pipe manufacturers, Sudhakar Group also provides CPVC pipes and other piping solutions that meet the highest industry standards.

In addition to their expertise in HDPE and plastic pipes, Sudhakar Group is also recognized as reliable wire and cable manufacturers, offering high-performance electrical wires and cables. Whether you're looking for HDPE pipes, electrical wire solutions, or UPVC windows and doors, Sudhakar Group provides everything you need to complete your project successfully, with products that are built to last and offer exceptional value.

#hdpe pipe manufacturers#hdpe pipe#cpvc pipe#wire and cable manufacturers#electrical wire#wire manufacturers#upvc window manufacturers#upvc windows and doors#upvc windows price

1 note

·

View note

Text

HDPE Plastic Sheet: A Comprehensive Overview

High Density Polyethylene (HDPE) Plastic Sheet has become an essential material in various industries due to its remarkable properties and versatility. This article aims to provide insight into HDPE plastic sheets, their applications, and the factors that influence HDPE Sheet Price in the market.

0 notes

Text

High Density Polyethylene (HDPE) Prices Trend | Pricing | News | Database | Chart

High-Density Polyethylene (HDPE) is one of the most widely used thermoplastic polymers, prized for its strength, durability, and versatility. It finds applications in a wide range of industries, from packaging to construction, automotive to consumer goods. As a key polymer in global markets, HDPE prices are subject to fluctuation, influenced by a variety of factors such as raw material costs, production capacities, supply and demand dynamics, and geopolitical events. Over the years, HDPE pricing has seen considerable volatility, which can impact production costs, profitability, and the final pricing of goods across sectors. The price trends of HDPE are of particular interest to manufacturers, suppliers, and buyers looking to optimize costs and make informed purchasing decisions.

One of the primary factors driving the prices of HDPE is the cost of its raw material: ethylene. Ethylene, which is primarily derived from natural gas or petroleum, is the building block for HDPE production. As such, fluctuations in global oil prices or changes in the availability of natural gas can significantly affect the cost of producing HDPE. In periods when crude oil prices rise due to geopolitical tensions, supply disruptions, or changes in global demand, the price of ethylene also increases, which, in turn, raises the price of HDPE. Conversely, when crude oil prices decrease, manufacturers may see lower HDPE production costs, leading to more favorable pricing in the market.

Get Real Time Prices for High-Density Polyethylene (HDPE) : https://www.chemanalyst.com/Pricing-data/hdpe-7

Another factor influencing HDPE prices is the global supply and demand balance. Demand for HDPE is strong in many sectors, including packaging, construction, agriculture, and automotive, as its chemical properties make it resistant to moisture, chemicals, and impact. It is used in a wide array of products, such as plastic bottles, pipes, and containers, as well as plastic films and liners. Any fluctuations in demand from these key industries can lead to price changes. For example, during periods of increased consumer demand for packaging or construction materials, the demand for HDPE can outstrip supply, leading to price hikes. Conversely, during periods of slower economic growth or reduced demand from key markets, prices may stabilize or fall.

The production capacity of HDPE manufacturers also plays a key role in determining price fluctuations. Overcapacity in the production of HDPE can lead to lower prices, as manufacturers compete to sell their products. However, when production is limited or reduced due to maintenance, plant closures, or capacity restrictions, the reduced supply of HDPE can cause prices to rise. In addition, factors such as the availability of feedstock, transportation costs, and infrastructure limitations can also influence the production costs associated with HDPE, thus affecting overall pricing trends.

Geopolitical factors and trade policies can further impact HDPE pricing, as these can affect the availability of raw materials, the cost of production, and the price of shipping. Trade tariffs and sanctions, for example, can increase the cost of importing or exporting HDPE, leading to higher prices in certain regions. Additionally, political instability in key HDPE-producing regions can disrupt supply chains, resulting in price hikes due to supply shortages. On the other hand, trade agreements and favorable policies may help stabilize prices by improving access to resources and reducing trade barriers.

Regional variations in HDPE prices are another important consideration. While the global price of HDPE can be influenced by many of the aforementioned factors, local market conditions can cause price differences in different regions. For example, regions with higher production capacities may see lower prices due to a more abundant supply, while regions with limited access to raw materials or production facilities may experience higher costs. The cost of labor, energy, and logistics in different regions also plays a role in determining local pricing trends. These regional disparities highlight the importance of keeping track of both global and local market developments when assessing the price of HDPE.

The rising demand for sustainable and eco-friendly materials has also impacted the pricing of HDPE in recent years. As environmental regulations tighten and consumer preferences shift toward more sustainable products, the cost of recycling HDPE and producing eco-friendly alternatives can drive prices up. The demand for recycled HDPE (rHDPE), in particular, has grown, as it is seen as an environmentally responsible alternative to virgin HDPE. However, the cost of processing and recycling HDPE can be higher, which can result in price increases for rHDPE products.

In addition to these fundamental factors, market speculation and trading in commodity markets can also contribute to short-term price fluctuations. Investors and speculators who trade HDPE futures contracts may drive prices higher or lower based on anticipated supply and demand conditions, geopolitical events, or broader economic trends. While these price swings are typically short-term in nature, they can still have a significant impact on the day-to-day pricing of HDPE in global markets.

For businesses that rely on HDPE as a key material in their production processes, staying informed about price trends is essential for making informed purchasing decisions. By closely monitoring market developments, raw material prices, and production capacities, companies can better anticipate price movements and adjust their purchasing strategies accordingly. Strategic sourcing, long-term contracts, and hedging strategies can all help mitigate the impact of price fluctuations and secure stable pricing for HDPE.

In conclusion, the prices of High-Density Polyethylene are influenced by a complex interplay of factors, including raw material costs, production capacities, supply and demand dynamics, geopolitical events, and regional market conditions. As a vital material used in a variety of industries, HDPE pricing can experience significant volatility, which affects the cost structure of many products. Understanding the factors that drive HDPE prices is crucial for businesses and consumers looking to navigate the ever-changing landscape of this essential polymer.

Welcome to ChemAnalyst App: https://www.chemanalyst.com/ChemAnalyst/ChemAnalystApp

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#HDPE Price#HDPE Prices#HDPE Pricing#High Density Polyethylene Price Monitor#High Density Polyethylene Price

0 notes

Text

Strengthening Infrastructure: Exploring Uniaxial Geogrids and Their Applications in Delhi

Uniaxial geogrids are pivotal in modern construction and civil engineering, providing enhanced stability and support to various structures. These geogrids, particularly those made from high-density polyethylene (HDPE), are renowned for their durability and effectiveness in soil reinforcement and load distribution. Delhi, with its rapidly growing infrastructure, has seen an increased demand for such materials, making the role of uniaxial geogrid manufacturers and suppliers in the region more critical than ever.

Understanding Uniaxial Geogrids

Uniaxial geogrids are a type of geosynthetic material used primarily for soil reinforcement. They are characterized by their high tensile strength in one direction, which makes them ideal for applications requiring significant resistance to tensile forces. These geogrids are commonly made from materials like HDPE, which offer excellent durability, chemical resistance, and long-term performance.

The Role of Geogrid Manufacturers in Delhi

As Delhi continues to expand its infrastructure, the demand for reliable construction materials like uniaxial geogrids has surged. Uniaxial geogrid manufacturers in Delhi are crucial in meeting this demand, offering products that meet stringent quality standards and cater to the specific needs of various construction projects.

These manufacturers employ advanced technologies and rigorous quality control measures to produce geogrids that offer exceptional performance and durability. By providing tailored solutions, they help engineers and builders in Delhi achieve optimal results in their projects, ensuring safety, efficiency, and longevity.

Pricing of HDPE Uniaxial Geogrids in India

The price of HDPE uniaxial geogrids in India varies based on several factors, including the specifications of the geogrid, the manufacturer, and the volume of the order. Generally, the HDPE uniaxial geogrid price in India is influenced by the tensile strength, thickness, and overall quality of the geogrid.

HDPE uniaxial geogrids are considered a cost-effective solution due to their long lifespan and low maintenance requirements. While the initial investment might be higher compared to other materials, the long-term benefits in terms of durability and performance make them a worthwhile investment for infrastructure projects.

Sourcing Uniaxial Geogrids in Delhi

Finding a reliable uniaxial geogrid supplier in Delhi is essential for ensuring the success of construction projects. A reputable supplier not only provides high-quality products but also offers technical support and guidance on the proper installation and use of the geogrids.

Suppliers in Delhi typically stock a range of uniaxial geogrids to meet different project requirements. They work closely with manufacturers to ensure that the geogrids meet the necessary standards and are delivered on time. By maintaining a robust supply chain, the Uniaxial geogrid supplier in Delhi help keep construction projects on schedule and within budget.

Conclusion

Uniaxial geogrids are indispensable in modern construction, offering unparalleled benefits in terms of soil reinforcement and structural stability. In Delhi, the demand for these geogrids is growing as the city continues to develop its infrastructure. By partnering with reliable uniaxial geogrid manufacturers and suppliers in Delhi, construction projects can achieve higher standards of safety, efficiency, and longevity. HDPE uniaxial geogrids, in particular, stand out for their durability and cost-effectiveness, making them a preferred choice for various applications. As the industry evolves, the role of these geogrids will only become more prominent, underpinning the growth and sustainability of Delhi's infrastructure.

Frequently Asked Questions

What are the primary uses of uniaxial geogrids? Uniaxial geogrids are mainly used for soil reinforcement in applications such as retaining walls, slope stabilization, embankments, road construction, and bridge abutments.

Why is HDPE a preferred material for uniaxial geogrids? HDPE is preferred for its excellent durability, chemical resistance, and long-term performance. It provides the necessary strength and stability for various construction applications.

How does the price of HDPE uniaxial geogrids compare to other materials? While the initial cost of HDPE uniaxial geogrids may be higher, their long lifespan and low maintenance requirements make them a cost-effective solution in the long run.

#uniaxial geogrid manufacturer in Delhi#hdpe uniaxial geogrid Price in India#uniaxial geogrid Supplier in Delhi

0 notes

Text

From Packaging to Piping: HDPE Sheets in Various Industries

High-density polyethylene (HDPE) sheets have revolutionized various industries due to their versatility, durability, and cost-effectiveness. Known for their high strength-to-density ratio, HDPE sheets have become indispensable in fields ranging from packaging to piping. This article explores the multifaceted applications of HDPE sheets and how they have become a vital component in numerous industrial processes. Keywords such as "hdpe sheet price," "hdpe sheet suppliers," and "hdpe sheet thickness" will also be discussed to provide a comprehensive understanding of this material's significance.

HDPE Sheets in the Packaging Industry

The packaging industry relies heavily on HDPE sheets due to their excellent moisture resistance, chemical resistance, and durability. These properties make HDPE sheets ideal for creating sturdy packaging that can protect goods during transportation and storage. HDPE sheets are used to produce a variety of packaging products, including bottles, containers, and liners. Their flexibility allows for easy molding into different shapes and sizes, catering to specific packaging needs.

The cost-effectiveness of HDPE sheets is another crucial factor for their widespread use in packaging. When considering the hdpe sheet price, businesses find that investing in HDPE packaging solutions offers a good return on investment due to their long lifespan and reliability. HDPE sheet suppliers provide a range of options in terms of size and thickness, ensuring that companies can find the perfect material to meet their packaging requirements.

HDPE Sheets in the Construction Industry

In the construction industry, HDPE sheets are valued for their robustness and resistance to environmental stress. They are used in various applications, including as liners for ponds and canals, as well as for roofing and wall protection. HDPE sheets provide an effective barrier against water and chemicals, making them ideal for waterproofing and protective layering.

The versatility of HDPE sheet thickness allows construction professionals to select the appropriate grade for different projects. Thicker sheets are used for applications requiring greater strength and durability, while thinner sheets are sufficient for less demanding tasks. The availability of HDPE sheets in various thicknesses from hdpe sheet suppliers ensures that construction projects can be completed with the most suitable materials, enhancing overall efficiency and durability.

HDPE Sheets in the Agricultural Sector

Agriculture is another industry that benefits significantly from the use of HDPE sheets. Farmers and agricultural businesses use these sheets for lining irrigation channels, creating durable storage tanks, and constructing greenhouses. The UV resistance and weatherproof nature of HDPE sheets make them ideal for outdoor agricultural applications.

The economic aspect, including the hdpe sheet price, plays a crucial role in their adoption in agriculture. HDPE sheets offer a cost-effective solution for long-term agricultural infrastructure. Additionally, hdpe sheet suppliers provide materials that are easy to handle and install, which is essential for large-scale agricultural operations. The varied hdpe sheet thickness options allow for customization according to the specific needs of different agricultural projects.

HDPE Sheets in the Automotive Industry

The automotive industry utilizes HDPE sheets in various components due to their lightweight and durable nature. HDPE sheets are used in manufacturing car parts such as fuel tanks, door panels, and fenders. The impact resistance and strength of HDPE make it an excellent material for these applications, contributing to vehicle safety and longevity.

The affordability and availability of HDPE sheets also play a significant role in their use in the automotive sector. The competitive hdpe sheet price ensures that manufacturers can produce high-quality parts without incurring excessive costs. HDPE sheet suppliers offer a range of thicknesses, allowing automotive engineers to select the most appropriate materials for different parts of the vehicle, optimizing performance and cost-efficiency.

HDPE Sheets in the Chemical Industry

In the chemical industry, the non-reactive and chemical-resistant properties of HDPE sheets are highly valued. These sheets are used to line chemical tanks, create protective barriers, and fabricate containers that store hazardous substances. The ability of HDPE sheets to withstand corrosive environments ensures the safe storage and handling of chemicals.

HDPE Sheets in the Marine Industry

The marine industry benefits from the use of HDPE sheets in the construction of boats, docks, and other water-related structures. HDPE sheets' resistance to water, salt, and UV radiation makes them ideal for marine applications. These sheets do not corrode or degrade easily, ensuring long-lasting performance in harsh marine environments.

HDPE Sheets in the Healthcare Industry

In healthcare, HDPE sheets are used to manufacture medical devices, hospital equipment, and sterile packaging. Their chemical resistance and ease of sterilization make HDPE sheets ideal for medical applications where hygiene and safety are paramount. HDPE sheets are also used to create clean room environments and protective barriers in medical facilities.

HDPE Sheets in the Environmental Sector

Environmental applications of HDPE sheets include waste management, landfill liners, and recycling systems. The durability and impermeability of HDPE sheets make them suitable for containing waste and preventing contamination. HDPE sheets are also used in the construction of recycling facilities and equipment, contributing to sustainable waste management practices.

The cost-effectiveness and availability of HDPE sheets are crucial for environmental projects, where budget constraints are often a concern. The competitive HDPE sheet price allows for the implementation of effective waste management solutions without compromising quality. HDPE sheet suppliers provide a range of thicknesses to meet the specific requirements of different environmental applications, ensuring that these projects are both efficient and sustainable.

Conclusion

HDPE sheets have proven to be a versatile and essential material across various industries. From packaging to piping, their applications are vast and varied, driven by their durability, chemical resistance, and cost-effectiveness. Keywords such as "hdpe sheet price," "hdpe sheet suppliers," and "hdpe sheet thickness" highlight the economic and practical considerations that make HDPE sheets a preferred choice in many fields. As industries continue to evolve and seek efficient, sustainable solutions, the role of HDPE sheets is likely to expand, further solidifying their place as a cornerstone material in modern industrial applications.

FAQs

What are the key benefits of using HDPE sheets? HDPE sheets offer several benefits, including high impact resistance, chemical resistance, moisture resistance, and durability. They are lightweight, easy to handle, and suitable for a wide range of temperatures.

Can HDPE sheets be recycled? Yes, HDPE sheets are recyclable. They can be reprocessed into new products, reducing plastic waste and contributing to environmental sustainability.

How to choose the right HDPE sheet suppliers? When choosing HDPE sheet suppliers, consider factors such as the supplier's reputation, product quality, customer reviews, and after-sales support. It's essential to ensure the supplier provides detailed information about the product specifications.

0 notes

Photo

Top HDPE Sheet Manufacturers in India - Top HDPE Sheet Manufacturers (on Wattpad) https://www.wattpad.com/1402323370-top-hdpe-sheet-manufacturers-in-india-top-hdpe?utm_source=web&utm_medium=tumblr&utm_content=share_reading&wp_uname=monoindustries2&wp_originator=%2B%2Fom4EhXfKzBFgiJGO5v3l5Bau9DoYfyqwGFb96XPyJt2SlaAm327EYCNZxwUFfJEnPbL9jFB%2FHVmDg5JtVzlh6gc2zibBYZ5GJJxRgujj5W7nUR9ParEpY9UnOdJhLV In the realm of industrial materials, High-Density Polyethylene (HDPE) sheets stand as versatile and indispensable components across diverse sectors. This blog delves into the intricate world of HDPE sheets, spotlighting the journey of a manufacturer dedicated to excellence, innovation, and the seamless integration of HDPE sheets into various applications.

#best#geomembrane#hdpe#hdpesheets#ldpe#lining#manufacturer#plastic#polythene#pond#price#quality#sheet#sheets#supplier#top#adventure#books#wattpad#amreading

0 notes

Text

Sudhakar Group is a leading HDPE pipe manufacturer offering high-quality HDPE pipes, CPVC pipes, and other plastic piping solutions. As trusted plastic pipe manufacturers, we provide durable, cost-effective products for diverse industries. Our HDPE pipes are known for their strength, longevity, and resistance to corrosion. We specialize in delivering reliable solutions for water, gas, and sewage systems. Sudhakar Group’s CPVC pipes offer excellent heat resistance and are ideal for plumbing applications. Explore our extensive range of HDPE pipes and CPVC pipes for all your construction needs. Trust Sudhakar Group for top-notch quality and performance."

This meta description efficiently incorporates all the target keywords while describing the products and brand strengths.

#hdpe pipe manufacturers#hdpe pipe#cpvc pipe#plastic pipe manufacturers`#wire and cable manufacturers#electrical wire#wire manufacturers#upvc window manufacturers#upvc windows and doors#upvc windows price

0 notes

Text

0 notes

Text

Cleflavron is a well established and recognized name in the recycling industry. Build on a history that dates back to more than 3 generations in the plastic, papers and metal scrap business.

#Pentium pro Intel Ceramic Cpu Scrap#scrap lead acid batteries#hot washed pet flakes scrap#hdpe milk bottle scrap supplier#aluminum scrap alloy wheels scrap price

0 notes